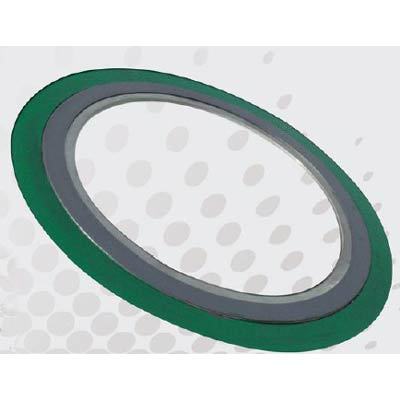

Spiral Wound Gasket

Product Details:

- Usage For Industrial Use

- Product Type Wound Gasket

- Shape Ring Gasket

- Click to View more

Spiral Wound Gasket Price And Quantity

- 1 Piece

- 10-10000 INR/Piece

Spiral Wound Gasket Product Specifications

- For Industrial Use

- Ring Gasket

- Wound Gasket

Spiral Wound Gasket Trade Information

- 200 Piece Per Day

- 1 Week

- All India

Product Description

Owing to our expertise in this domain, we are engaged in offering an excellent quality array of Spiral Wound Gasket that is suitable for sealing purpose. The offered gasket is made by winding alternating strips of metal and soft filler material with the help of advanced technology with high precision. This gasket is used in refinery & chemical processing plants, power generation, aerospace, also can be changed to accommodate different chemical compatibility requirements. Further, this Spiral Wound Gasket is available in various specifications as per the requirements of the clients.

Features:

-

Corrosion resistant

-

Durability

-

Wear & tear resistance

-

Highly flexible

Other information

Wound Gasket

Spiral wounds gaskets have proven themselves to be the most reliable sealing element for use in variety of conditions and applications. These are made by winding alternating strips of metal and soft filler material. A 'V' or 'W' shaped crown centered in the metal strip acts as a spring, giving gaskets greater resiliency under varying conditions. Filler and winding material can be changed to accommodate different chemical compatibility requirements. Widely used throughout refineries and chemical processing plants, spiral wound gaskets are also effective for power generation, aerospace, and a variety of valve and specialty applications.

Spiral wound gaskets are manufactured as per ASME/ANSI B16.5 (API 601), ASME B16.47 Series A (MSS-SP44), ASMEB16.47 Series B (API 605), BS 1560, BS 4504, BS 10, DIN/EN 1092, JIS Flanges and French NF standard.

Size and shape as per prevailing international standards or customer need can be produced

Technical Specifications

| Filler Material | Recommended Maximum Temperature | ASME B16.20 Color Coding |

|---|---|---|

| Graphite | 550oC | Grey stripe |

| PTFE | 260oC | White stripe |

| Non Asbestos/CAF | 350oC | White/Pink stripe |

| Ceramic | 650oC | |

| Winding Material | Recommended Maximum temperature | ASME B16.20 Color coding |

| 304/304L stainless steel | 650oC | Yellow |

| 316/316L stainless steel | 650oC | Green |

| 347 Stainless steel | 650oC | Blue |

| 321 Stainless steel | 650oC | Turquoise Blue |

| Monel 400 | 600oC | Orange |

| Nickel 200 | 600oC | Red |

| Titanium | 350oC | Purple |

| Inconel 600 | 950oC | Gold |

| Titanium | 350oC | Purple |

| Inconel 600 | 950oC | Gold |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sprial Wound Gasket' category

|

LEAK CONTROL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS